WASHINGTON — Amtrak’s Office of Inspector General has released a report explaining how the company’s lack of effective parts inventory management is responsible for numerous service failures.

The 62-page report released Monday, “Asset management: Company has opportunities to more effectively manage and safeguard maintenance of equipment inventory,” asserts a lack of key parts to keep locomotives and passenger cars rolling has prompted mechanical department employees to take missing items from other equipment. The decision to delay restoration of Amtrak’s passenger car and locomotive fleet to pre-COVID 19 pandemic levels means there is less available rolling stock to “cannibalize,” resulting in tardy departures, cancellations, and “customer experience” downgrades.

On the other hand, the report found that as of September 2023, Amtrak was incurring expenses on $49 million worth of surplus or obsolete parts inventory it no longer needs.

During the past year, Inspector General analysts interviewed 145 material control group and mechanical department employees at 10 Amtrak facilities around the country. About 31% of these workers said it was a daily occurrence that a part they needed was unavailable; during later visits, 87% said it happened every week.

In calendar 2022, 900 pieces of equipment were sidelined a total of 13,000 days while out‐of‐stock inventory items were forwarded via expedited shipping. “Senior Mechanical officials agreed that unavailable inventory limits service capacity,” the report notes, “but the company does not know the extent to which unavailable inventory impacts operations because it does not track this information.”

Employees told interviewers they “must cannibalize parts every day while waiting for the facility to receive more stock, which can sometimes take several months. Time spent removing parts from other units increases mechanical employees’ workloads, but many told us they continue doing this to avoid holding units from service and to ensure that trains leave their facility on time.”

Researchers were told by all mechanical department employees spoken to during later site visits that “unavailable parts and materials affect morale at their facility to at least a moderate extent.”

Workers at several of the facilities said lack of parts led to departure delays and trains leaving terminals without sleeping or dining cars, forcing customer downgrades or compensation, but the report says Amtrak doesn’t track that information either.

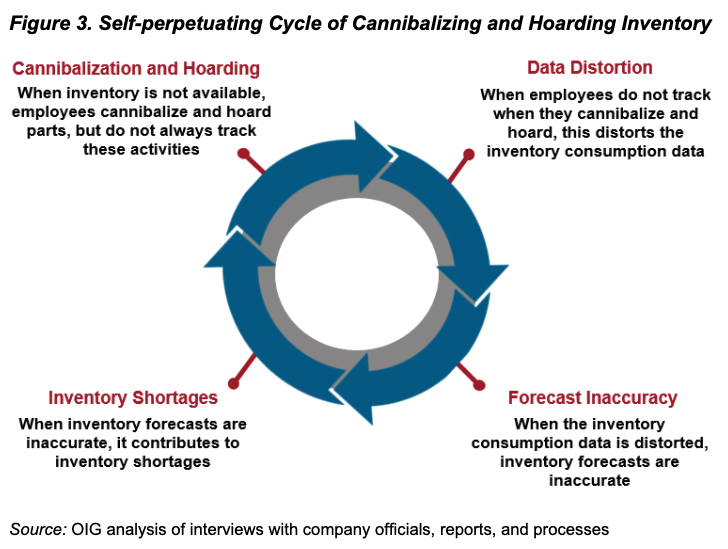

Widespread parts shortages have also led to hoarding at many locations, which exacerbates the inventory imbalance shown in the report’s portrayal of a “self-perpetuating cannibalizing cycle.”

Amtrak management agreed to implement a series of seven recommended improvements to its parts ordering system, inventory controls, and tracking of delays caused by lack of spare parts as outlined in Appendix E at the end of the report. Most target completion dates for the reforms range from Sept. 30, 2024, to early 2025.

— Updated at 9:35 a.m. CT to clarify that parts cannibalized were not necessarily from operational equipment, and information on worker responses to question regarding parts unavailability.

Meanwhile, back in 1972…

“Amtrak was incurring expenses on $49 million worth of surplus or obsolete parts inventory it no longer needs.” Only a government run monopoly would get away with this.

Let slow down on this. After some consideration what is Amtrak doing with these parts? Does Amtrak transfer some of these parts to various locations that may need one of these parts? If say a number of F-40s go to different parties none which could never need a part “A” but maybe someone else needs a part “A”. but not a part “B”.

Do we know if some of these parts are for say EX Santa Fe high level cars? The list of single item unique equipment for museums could go on and on as well. No parts there goes your favorite museum closing for no operable equipment. It already happens.

Are some of these parts unique to the cars that VIA operates and is having difficulty maintaining the cars as public ally acknowledged?

The worst thing that could happen is for these parts to be declared scrap and get melted. That without making sure that no one has use for them.

In the automotive world, part availability is still a real problem. Manufacturing is still a problem for most suppliers. It might have just become a reality and that’s the way it is and will stay. I can’t imagine it gets any better in heavy industry.

Precision Scheduled Bureaucracy.

I have to listen to the same Hooey Amtrak is in my line of work. Did all of Americas factories just shut down for good ? do they only come to work on days when there is an order to fill ? The manufacturing level in this Country should have returned to pre COVID levels by now. Oh, that’s right, You can continue to bust my skull on costs if You claim low or no stock can’t You ? I don’t blame Amtrak or it’s management. I blame the private industry that wants to keep profits at an unreasonable level claiming supply chain issues.

Robert,

Exactly how do you define an “unreasonable level”?

Amtrak is the overall problem. It just can’t get its act together.

One major challenge is the age of many Amtrak cars, especially those from defunct builders. Parts for these are often not “on the shelf” and available overnight. But history records from past repairs should identify what critical items are frequently needed to allow advance stocking.

The report’s statistical methodology seems a bit dodgy. 87% of workers experiencing parts shortages doesn’t mean that 87% of parts are unavailable. For all that, this report is horrendous. The people not now riding Amtrak because of its unreliability aren’t going to come back. Oh and BTW, I’m one of those.

Those much-maligned pre-Amtrak private railroads in retrospect are looking real good. From ATSF at the top end of rolling stock maintenance, to New Haven Railroad at the other end of the scale, the trains ran.

Why am I not surprised to read this? Amtrak has only had 53 years to figure out how to do this. Give them a chance. No piling on.